Superabsorbent Ultra Thin Cores and Airlaids for

Wound Care

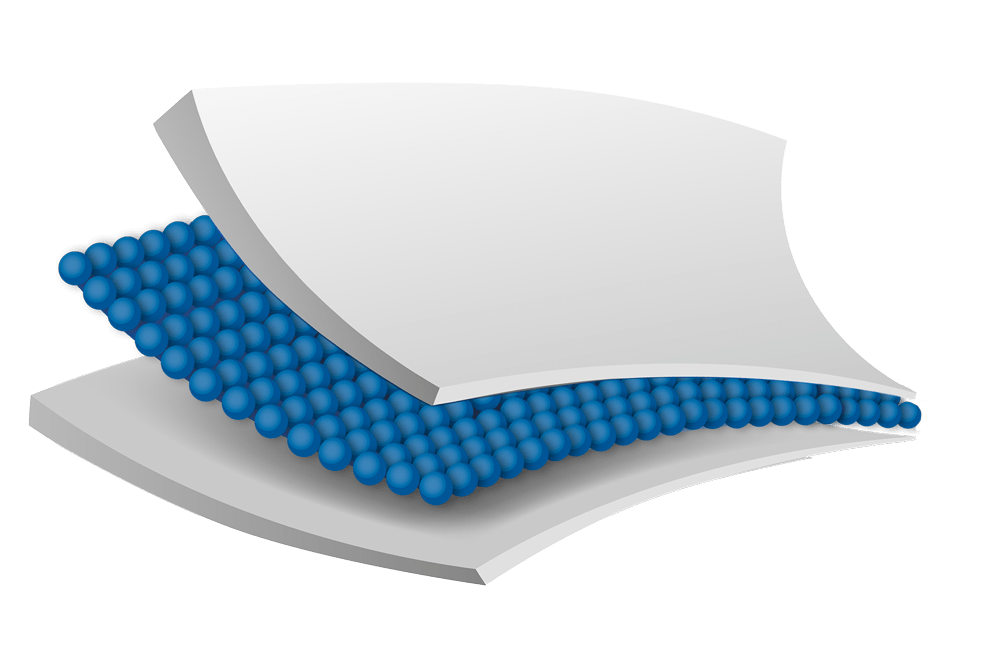

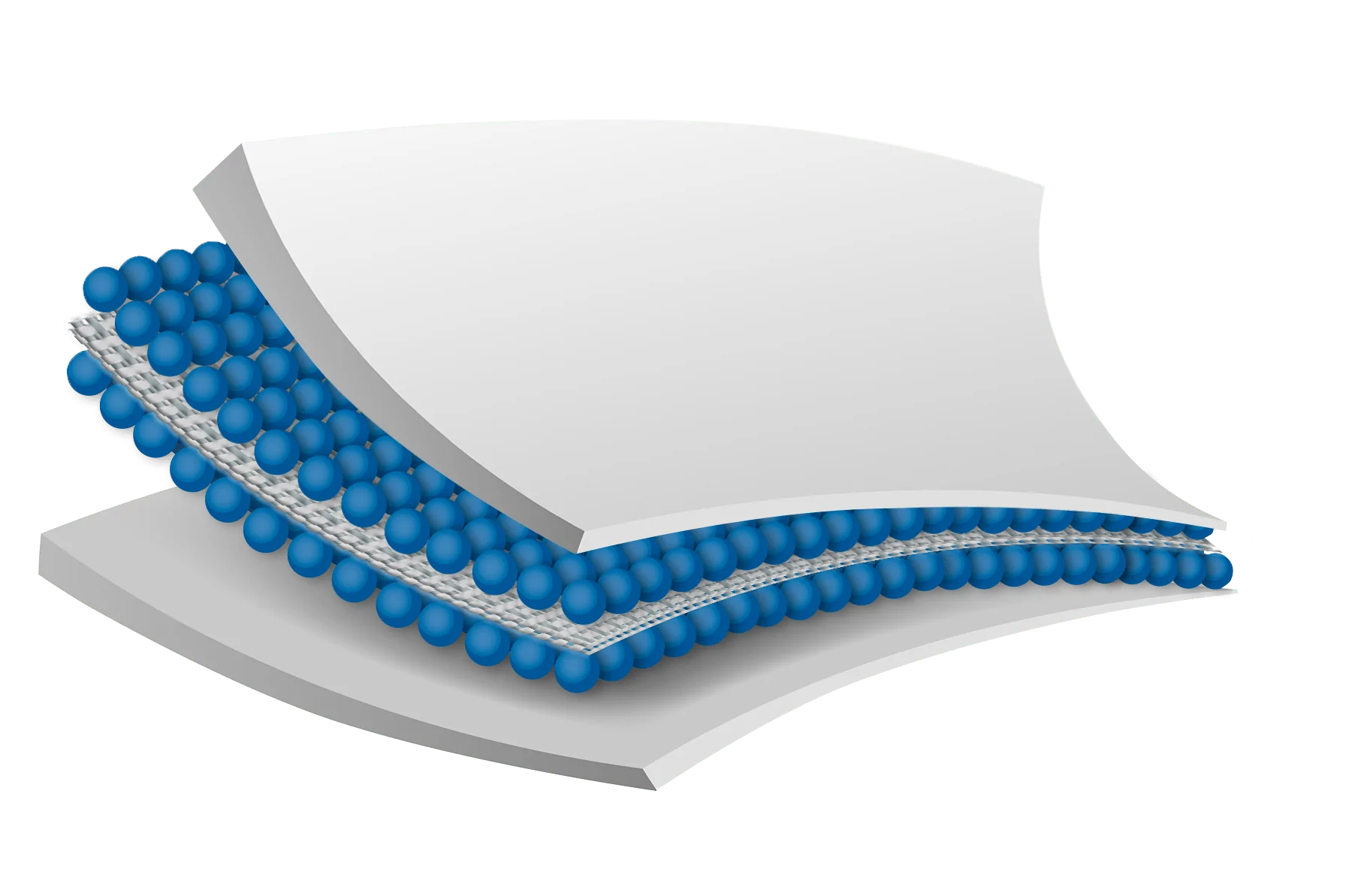

Gelok superabsorbent laminates for wound care and TotalCore airlaids utilize medical grade superabsorbent polymers that can absorb many times their weight in exudate and blood and lock it in with high retention capacity.

“Lok” in on Healing

Because liquids are physically bound to the SAP they will not be released even under relatively high pressure. These qualities make Gelok superabsorbent laminates for wound care ideal for use in wound dressings and other disposable medical devices. Superabsorbent laminates can also be constructed from non-woven substrates by incorporating medical grade adhesives.

Wound Care Applications

- Foam dressings

- Superabsorbent dressings

- Island dressings

- Burn care dressings

- IV site care

- Ostomy care

- Breathable film

- Non-woven products

- Hydrocolloid dressings

- Film dressings

Features & Benefits

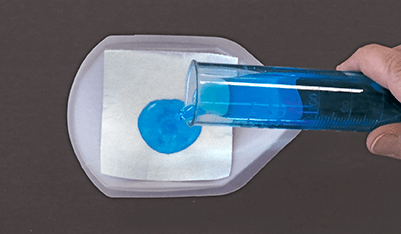

- Can be easily cut for island placement into wound dressings

- Quickly wick away liquids, keeping acquisition layer dry to the touch

- Will not release liquid when moderate pressure is applied

- Odor controlling

- Ultra-thin finished products

- Decreased maceration of wound bed

- Can be manufactured with a variety of substrates to meet customer needs

- Customizable absorbency levels

Sizes & Absorbencies

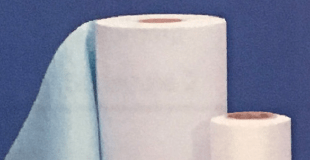

- 52” to 1.5” (1210 mm to 38 mm) Gelok laminate slit widths available

- Up to 28” OD laminate rolls with 3” cores

- Up to 55″ OD TotalCore airlaid rolls with 3″ or 6″ cores

- 100 to 1500 g/sq ft absorbency

- Custom sizes and absorbencies available upon request

Technical Data

Gelok 5040-72 S/S

Pad Construction / Description

A light weight laminate that can be used for slight to moderate exuding wounds. Absorbency can be adjusted to suit the anticipated amount of exudate and the target length of time over the wound.

Absorbency Rating

Typical expected absorbency would be ~2,500 grams per square meter of 0.9% saline solution and over 5,000 grams per square meter of 0.2% saline solution.

Gelok 15040-72 S/S

Pad Construction / Description

A light weight laminate that can be used for slight to moderate exuding wounds. Absorbency can be adjusted to suit the anticipated amount of exudate and the target length of time over the wound.

Absorbency Rating

For this laminate, absorbency would be ~7,500 grams per square meter of 0.9% saline solution and over 15,000 grams per square meter of 0.2% saline solution.

Gelok 30040-72 S/S

Pad Construction / Description

A medium absorbency laminate used for moderate to heavily exuding wounds. The absorbency can also be adjusted to accommodate the anticipated length of time the dressing will be in contact with the wound.

Absorbency Rating

This is one of our highest absorbency laminates with an expected absorbency of ~15,000 grams per square meter of 0.9% saline solution and 30,000 grams per square meter of 0.2% saline solution.

Contact Us for Technical Advice

Fill out the form below to order samples, get more information or leave feedback.

Please let us know if you have any questions, and your Gelok representative will reach out shortly.

Gelok Services

Custom Manufacturing

- Pilot machine testing

- Research and development

- Experienced engineering/chemical staff

Technical Services

- Superabsorbent product design

- Equipment/system design

- Fully equipped laboratory

- Training and education (products and systems)

- Custom services as required

Materials Testing

- Tensile strength

- Absorption rates

- Fluid retention

- Other testing as required

Gelok Laminate Slitting

- Widths from 1-1/2″ (38 mm) to 52″ (1321 mm)

- Untrimmed master roll at 54″ (1370 mm) or 50″ (1270 mm)

- 3″ (75 mm) OD core

- Standard OD 28″ (711 mm)

TotalCore Airlaid Slitting

- 30” to 1.5” (910 to 38 mm) slit widths available

- Up to 50” OD rolls with 3″ or 6″ cores