TotalCore airlaid composites

A ‘Total’ package for flexibility, softness and superior absorbency.

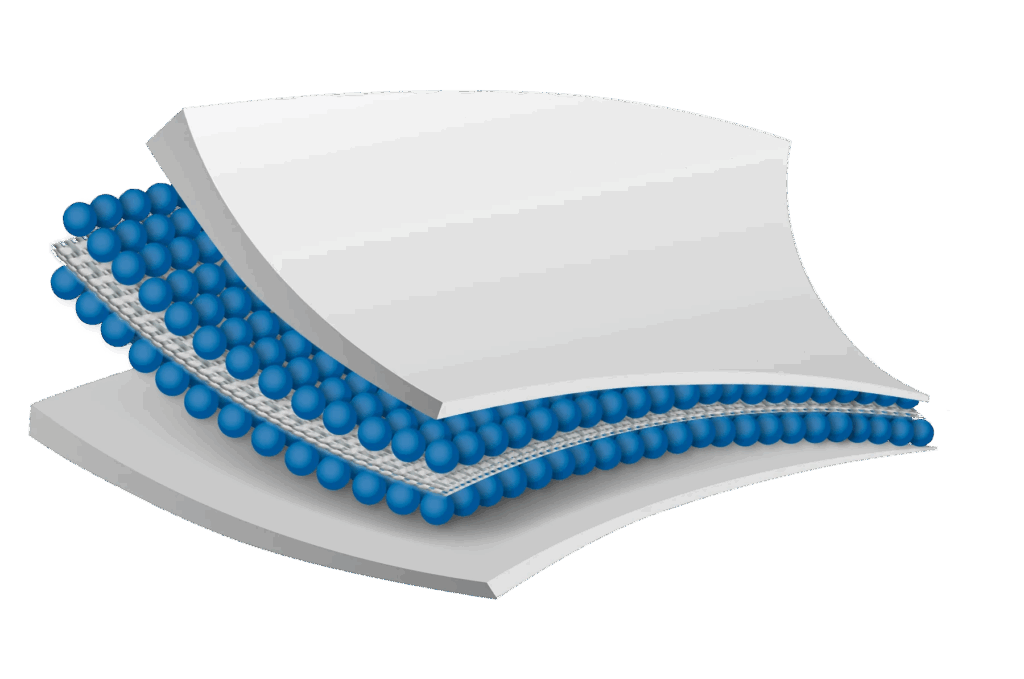

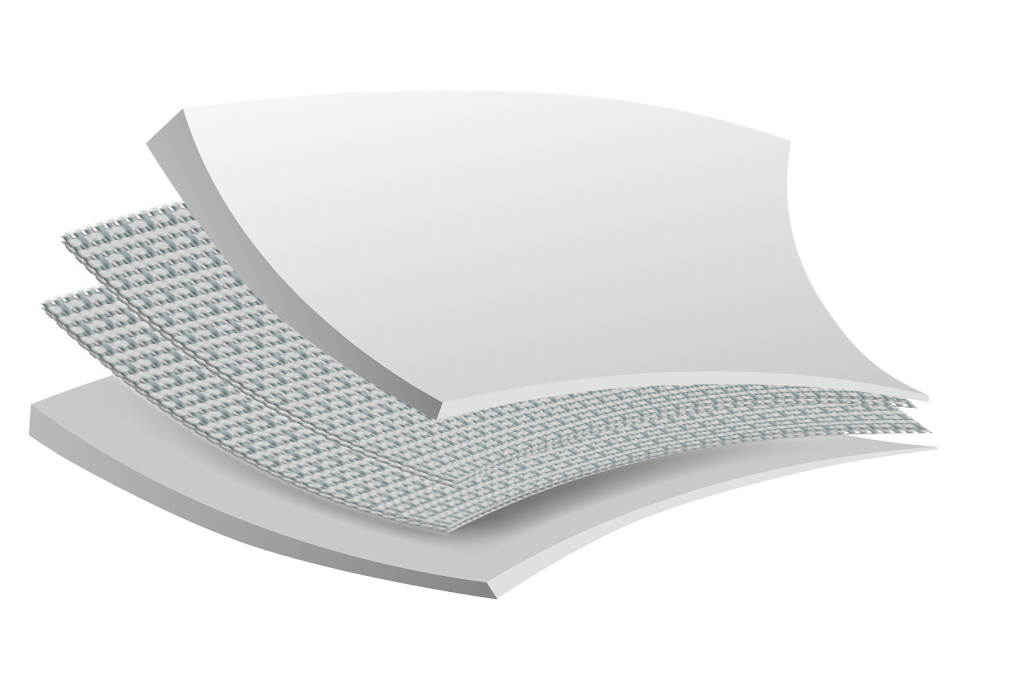

Ultra-thin and ultra-soft Airlaid Composites

TotalCore airlaid composites are made from all-natural cellulose fibers and are hydrogen bonded without latex or resin binders. The airlaid can be customized with a variety of substrates, superabsorbent polymers and cellulose fibers to meet specific absorbency and performance needs. They are soft, flexible and provide excellent liquid distribution for superior absorbency. TotalCore airlaids are of exceptional quality, produced on state of the art equipment and are available as master rolls, ‘pancake’ reels or festooned bales.

Features & Benefits

- Extraordinarily thin profile: Ultra-thin and ultra-soft designs for greater comfort

- Excellent liquid distribution properties for superior absorbency

- Hydrogen bonded, no latex or resin binders

- Flexible & lightweight for reduced package sizes and logistics costs

- Lightweight, less bulky

- Customizable structure to meet specific performance requirements

- Rapid absorption (actual speed of absorbency varies by application and product design)

- Consistent finished product

- Easy-to-use commercial forms – Master rolls, ‘pancake’ reels or festooned bales

Sizes & Absorbencies

- Custom absorbencies and sizes are available upon request

- 36” to 1.5” (910 mm to 38 mm) slit widths available

- Up to 60” OD rolls

Acquire

Rapid acquisition of aqueous fluids

Distribute

Effective distribution of fluids throughout the entire core

Absorb

Powerful absorption locks in fluids and odors

About our Airlaids

TotalCore Airlaid Applications

TotalCore Airlaid Composites for Feminine Hygiene

TotalCore airlaid composites for feminine hygiene are characterized by their ultra-thin profile, softness, and superior flexibility, making them an ideal choice for use in feminine protection and personal care products.

Features & Benefits

- High absorbency

- Excellent fluid retention and moisture control

- Lightweight, Ultra-thin design

- Excellent fluid distribution for superior absorbency

- Formulated with or without superabsorbent polymer

TotalCore Airlaid Composites for Food Packaging

TotalCore airlaid composites for food packaging are made with FDA approved food grade superabsorbent polymers and all natural cellulose fibers, making them a safe choice for use with poultry, seafood, meat, and fruit. Used as the absorbent core, TotalCore airlaid composites lock fluid into a solid gel, reducing excess meat juice, odors and bacteria.

Features & Benefits

- Clean looking packages are more appealing

- Absorbing surplus meat juices reduces microbes and increases shelf life

- Customized absorbencies to hit targeted fluid control

- Reduces growth of microbes

TotalCore Airlaid Composites for Medical Applications

TotalCore airlaid composites for medical applications are ultra-thin while being extremely absorbent, therefore, requiring less absorbent media. TotalCore airlaids are ideal as the absorbent core in hospital, surgery pads, and in body/cadaver bags Ultra-thin designs with superior absorbent properties are an ideal solution for reducing logistics costs and containing infectious substances.

Features & Benefits

- Ultra-thin designs with high absorbent properties

- Cost-effective solutions for shipping

- Biohazard bags

- Pneumatic tube transport

- Medical packaging kits

- Infectious substance shipping

- Body / cadaver bags

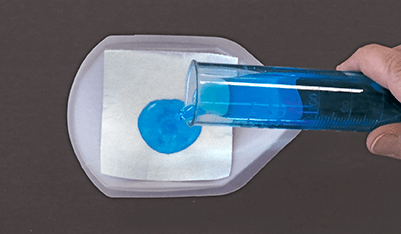

TotalCore Airlaid Composites for Wound Care

TotalCore airlaid composites for wound care utilize customized superabsorbent polymers that absorb many times their weight in exudate and lock it in with high retention capacity. Because liquids are locked by hydrogen bonding, they will not be released even under relatively high pressure. These qualities make TotalCore superabsorbent wound care airlaids ideal for use in wound dressings and other disposable medical devices.

Features & Benefits

- Ultra-thin/Ultra-soft designs

- Drapable and Conformable

- Superabsorbent polymers customized to application for enhanced performance

- Excellent liquid distribution for superior absorbent capacity

- Hydrogen bonded – no chemical binders or adhesives

Technical Data

TotalCore

For Feminine Hygiene

Characterized by their ultra-thin profile, softness, and superior flexibility.

Sizes & Absorbencies

- Master rolls up to 36” wide

- Slit into pancake rolls (down to 1.5”/38 mm)

- Converted into festooned bales

TotalCore

For Food Packaging

Made with FDA approved food grade cellulose with or without superabsorbent polymers.

Sizes & Absorbencies

- 36″ to 1.5″ (910 to 38 mm) slit widths available

- 3″ or 6″ cores

- 100 to 1500 g/sq. ft absorbency

TotalCore

For Medical Applications

Ultra-thin while being extremely absorbent, therefore, requiring less absorbent media.

Sizes & Absorbencies

- 36” to 1.5″ (910 to 38 mm) slit widths available

- Up to 60″ OD rolls with 3″ or 6″ cores

- 100 to 1500 g/sq ft absorbency

TotalCore

For Wound Care

Medical grade superabsorbent polymers that absorb many times their weight in aqueous exudate and lock it in with high retention capacity.

Sizes & Absorbencies

- 36” to 1.5” (910 to 38 mm) slit widths available

- Up to 60” OD rolls with 3″ or 6″ cores

- 100 to 1500 g/sq ft absorbency

- Custom absorbencies and sizes available upon request

Gelok Services

Custom Manufacturing

- Pilot machine testing

- Research and development

- Experienced engineering/chemical staff

Technical Services

- Superabsorbent product design

- Equipment/system design

- Fully equipped laboratory

- Training and education (products and systems)

- Custom services as required

Materials Testing

- Tensile strength

- Absorption rates

- Fluid retention

- Other testing as required

Gelok Laminate Slitting

- Widths from 1-1/2″ (38 mm) to 52″ (1321 mm)

- Untrimmed master roll at 54″ (1370 mm) or 50″ (1270 mm)

- 3″ (75 mm) OD core

- Standard OD 28″ (711 mm)

TotalCore Airlaid Slitting

- 30” to 1.5” (910 to 38 mm) slit widths available

- Up to 50” OD rolls with 3″ or 6″ cores