Superabsorbent Ultra Thin Cores and Airlaids for

Filtration

Our superabsorbent laminates for filtration are designed for use by manufacturers and designers of filtration, separation, coalescing, and dehydration systems.

‘Lok’ in on clean products and systems

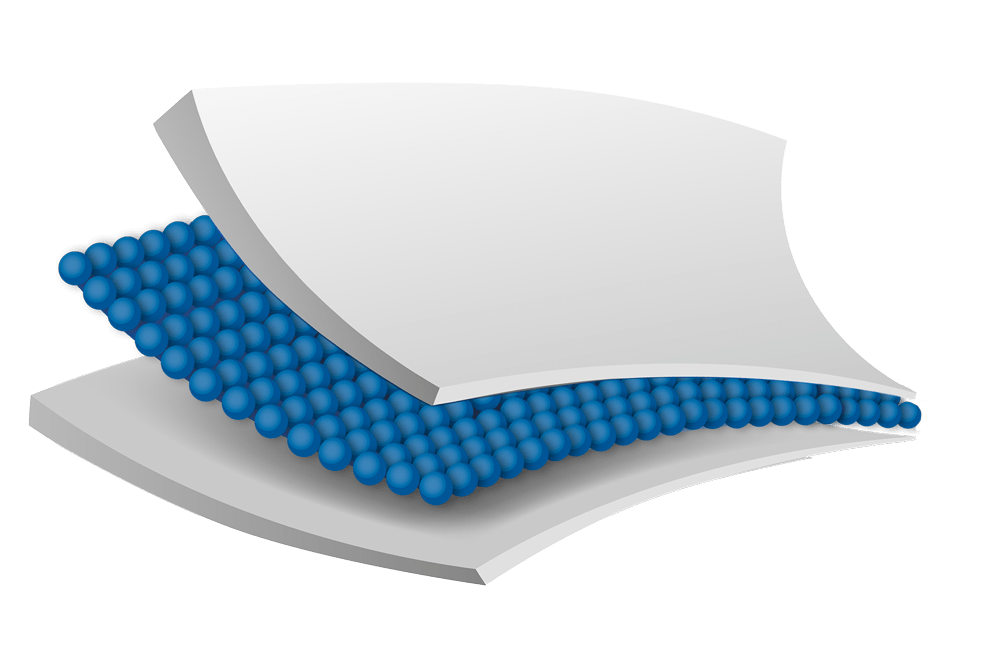

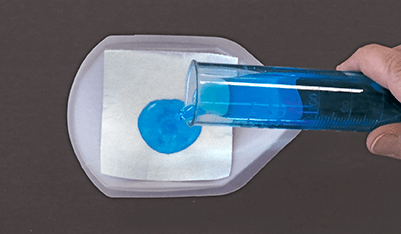

Gelok Water Absorber Filter Laminates can enhance filtration system efficacy by selectively absorbing free water present in fuel and oil, including hydraulic oil, insulating oil, gasoline, diesel, jet fuel, and kerosene. When absorbed, the water is locked physically by hydrogen bonding and will not be able to return to the fuel. Removing water results in extended usable oil life, decreased system down time, and ultimately increased life of equipment.

Gelok superabsorbent media’s ultra-thin profile and very high absorbency capacity makes it an ideal choice for use in filtration systems for water removal. Absorbency levels can be customized for specific separation and absorbent challenges. Gelok superabsorbent media is easily incorporated into existing systems or into new filtration designs.

Filtration Applications

- Gasoline

- Kerosene

- Diesel fuel

- Insulating oil

- Transformer oil

- Hydraulic oil

- Turbine Lube oil

- Quench oil

- Synthetic oil

- Phosphate Ester oil

- Instrument air

- Process gases

Features & Benefits

- Three Absorbency Speeds – Slow, medium, and fast absorption rates are available to match the speed needed for your application.

- Excellent absorbency with ultra thin profile

- Easily incorporated into existing filtration systems

- Decreases equipment and system downtime

- Increases in fuel efficiency

- Extends the life of critical equipment

Sizes & Absorbencies

Laminates for absorption of hazardous wastes can be tailor-made to suit specific applications with absorbencies up to 7,500 grams per meter squared of 0.9% saline solution. Rolls can be up to 52″ wide and lengths as required.

Technical Data

Gelok 5040-72

Pad Construction / Description

A light weight laminate for low absorbency requirements

Absorbency Rating

Available on request

Gelok 9540-72

Pad Construction / Description

A medium weight laminate for intermediate absorbency requirements

Absorbency Rating

Available on request

Gelok 30040-76

Pad Construction / Description

A heavy weight laminate for the highest of absorbency requirements

Absorbency Rating

Available on request

Contact Us for Technical Advice

Fill out the form below to order samples, get more information or leave feedback.

Please let us know if you have any questions, and your Gelok representative will reach out shortly.

Gelok Services

Custom Manufacturing

- Pilot machine testing

- Research and development

- Experienced engineering/chemical staff

Technical Services

- Superabsorbent product design

- Equipment/system design

- Fully equipped laboratory

- Training and education (products and systems)

- Custom services as required

Materials Testing

- Tensile strength

- Absorption rates

- Fluid retention

- Other testing as required

Gelok Laminate Slitting

- Widths from 1-1/2″ (38 mm) to 52″ (1321 mm)

- Untrimmed master roll at 54″ (1370 mm) or 50″ (1270 mm)

- 3″ (75 mm) OD core

- Standard OD 28″ (711 mm)